|

|

| Brand Name: | CHEEBO Technology |

| Model Number: | CBLD-26 |

| MOQ: | 1 set |

| Price: | NEGOTIABLE |

| Packaging Details: | Marine moisture-proof wooden case |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram, |

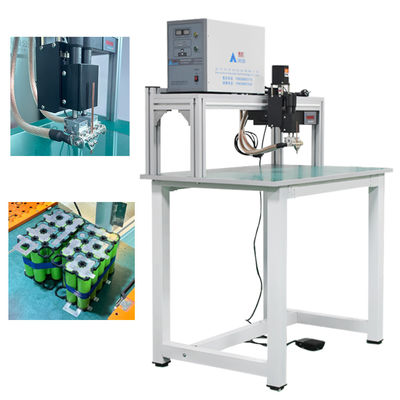

● The lithium battery spot welding machine adopts a pure electric design without a cylinder, resulting in low noise and stable pressure.

● It is driven by a motor and precisely controlled by a control box, offering three adjustable modes.

●The CBLD-26 multi pulse lithium battery spot welding machine adopts a proprietary output energy optimization algorithm to ensure a reasonable conversion between output voltage and output current. This results in strong welding capabilities, safe welding, no virtual welding, minimal sparks, and excellent surface quality.

● Precisely developed welding heads allow for precise pressure adjustment and control.

● Microcomputer technology is employed for control.

● Applicable battery specifications: minimum not less than 50MM, maximum not more than 130MM (can be used for height increase type).

● The welding platform adopts high quality tempered glass to protect the desktop from wear and tear during the welding process.

● Vertical spot welding method is spot welding, manual control of pressure depth.

● Digital LED display, equipment parameters adjustment is more intuitive, easy to learn and easy to operate.

● Welding machine can be pre-stored multiple procedures, can be changed and called at will.

● Compact structure, small volume, high power, large industrial circuit design, safe and reliable welding process

1.Adjusting mechanism of welding head.

The welding head can be adjusted up and down to increase the distance between the desktop and the welding head. Can weld a variety of different heights, different types of cells.

![]()

2.Electric welding head

CHEEBO's independently developed precision welding machine head. The welding pressure can be precisely adjusted and equipped with a buffering pressure adjustment mechanism, which can effectively reduce damage to the battery during the welding process. No need to configure an air pump; Adopting single axis stepper drive control, it runs smoothly.

![]()

3. Electric control

No additional air source, low noise, fast welding speed, stable pressure.

![]()

| Welding thickness | 0.02-0.18MM | Welding power supply | Multiple-pulse |

| Welding mode | Single side double point horizontal welding | Table top and weld head height | 130MM (Maximum pitch adjustable) |

| Supply current | 3000A | Welding speed | 180P/M |

| Spot welding method | Bump welding/tip welding | Welding pressure | 5KG/F |

| Equipment power | 12KW | Equipment size | 600*900*1300MM |

| Driving mode | Electric | Machine Weight | 60KG |

| Power source specification | Single-phase 220V50/60HZ | Application scenarios | Battery welding |

![]()

![]()

![]()

![]()

Q: How do I install and run the machine?

A: Our technicians had installed the machine before shipment. For the installation of some widgets, we will send out detailed training videos and user manuals randomly. 95% of customers can teach themselves.

Q: How can I do if the machine goes wrong?

A: If you encounter such problems, please contact us as soon as possible. Do not try to repair the machine by yourself or others. We will respond as soon as possible within 24 hours to solve your problem.

Q: I don't know which one is right for me?

A: Please tell us the following information

1) Battery model and type.

2) Welding material and welding thickness

3) Commercial industry: We have a lot of sales experience and can provide you with advice.

Q: What's your minimum order quantity?

A: We don't have a minimum order quantity. Whether it is an order of 1 or 100, we will wholeheartedly support you.

Q: How does your factory do in terms of quality control?

A: Quality comes first. More than 20 tests will be performed on each unit. After all the tests are passed, our QC will test the welding performance.

![]()

|

| Brand Name: | CHEEBO Technology |

| Model Number: | CBLD-26 |

| MOQ: | 1 set |

| Price: | NEGOTIABLE |

| Packaging Details: | Marine moisture-proof wooden case |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram, |

● The lithium battery spot welding machine adopts a pure electric design without a cylinder, resulting in low noise and stable pressure.

● It is driven by a motor and precisely controlled by a control box, offering three adjustable modes.

●The CBLD-26 multi pulse lithium battery spot welding machine adopts a proprietary output energy optimization algorithm to ensure a reasonable conversion between output voltage and output current. This results in strong welding capabilities, safe welding, no virtual welding, minimal sparks, and excellent surface quality.

● Precisely developed welding heads allow for precise pressure adjustment and control.

● Microcomputer technology is employed for control.

● Applicable battery specifications: minimum not less than 50MM, maximum not more than 130MM (can be used for height increase type).

● The welding platform adopts high quality tempered glass to protect the desktop from wear and tear during the welding process.

● Vertical spot welding method is spot welding, manual control of pressure depth.

● Digital LED display, equipment parameters adjustment is more intuitive, easy to learn and easy to operate.

● Welding machine can be pre-stored multiple procedures, can be changed and called at will.

● Compact structure, small volume, high power, large industrial circuit design, safe and reliable welding process

1.Adjusting mechanism of welding head.

The welding head can be adjusted up and down to increase the distance between the desktop and the welding head. Can weld a variety of different heights, different types of cells.

![]()

2.Electric welding head

CHEEBO's independently developed precision welding machine head. The welding pressure can be precisely adjusted and equipped with a buffering pressure adjustment mechanism, which can effectively reduce damage to the battery during the welding process. No need to configure an air pump; Adopting single axis stepper drive control, it runs smoothly.

![]()

3. Electric control

No additional air source, low noise, fast welding speed, stable pressure.

![]()

| Welding thickness | 0.02-0.18MM | Welding power supply | Multiple-pulse |

| Welding mode | Single side double point horizontal welding | Table top and weld head height | 130MM (Maximum pitch adjustable) |

| Supply current | 3000A | Welding speed | 180P/M |

| Spot welding method | Bump welding/tip welding | Welding pressure | 5KG/F |

| Equipment power | 12KW | Equipment size | 600*900*1300MM |

| Driving mode | Electric | Machine Weight | 60KG |

| Power source specification | Single-phase 220V50/60HZ | Application scenarios | Battery welding |

![]()

![]()

![]()

![]()

Q: How do I install and run the machine?

A: Our technicians had installed the machine before shipment. For the installation of some widgets, we will send out detailed training videos and user manuals randomly. 95% of customers can teach themselves.

Q: How can I do if the machine goes wrong?

A: If you encounter such problems, please contact us as soon as possible. Do not try to repair the machine by yourself or others. We will respond as soon as possible within 24 hours to solve your problem.

Q: I don't know which one is right for me?

A: Please tell us the following information

1) Battery model and type.

2) Welding material and welding thickness

3) Commercial industry: We have a lot of sales experience and can provide you with advice.

Q: What's your minimum order quantity?

A: We don't have a minimum order quantity. Whether it is an order of 1 or 100, we will wholeheartedly support you.

Q: How does your factory do in terms of quality control?

A: Quality comes first. More than 20 tests will be performed on each unit. After all the tests are passed, our QC will test the welding performance.

![]()